Copyright © Dongguan Lijing Chemical Trading Co., Ltd. All Rights Reserved. Site Map

- +86-13509219524

- dglijingch@yeah.net

- Room 1406, Fuxi Building, No. 33, Keyuan South Road, Guancheng Subdistrict, Dongguan City

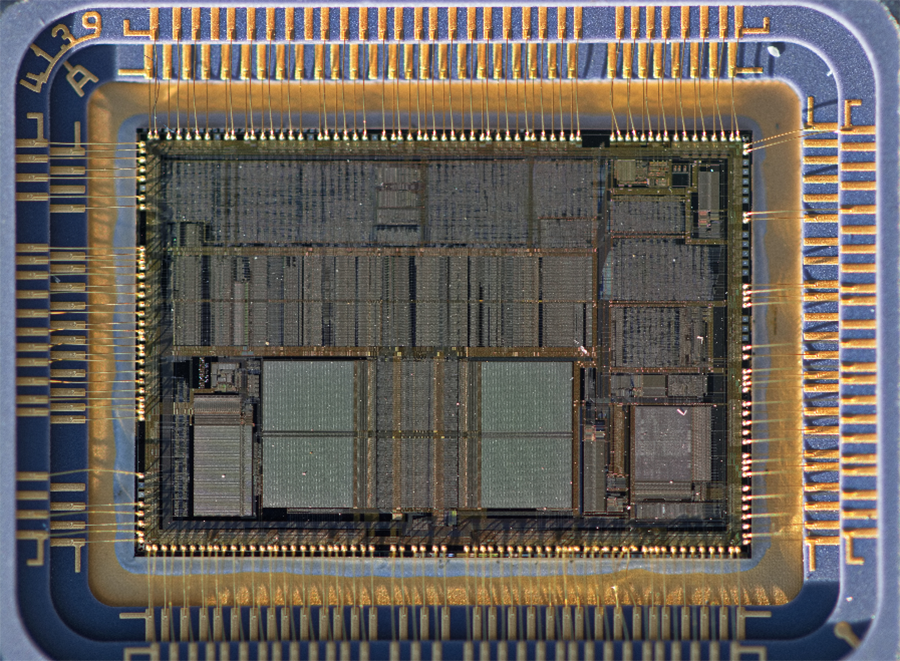

With the rapid development of electronic processes, the operating frequency of semiconductor chips is getting higher and higher, the size is getting smaller and smaller, and the integration is getting higher and higher. The cleaning of semiconductor chip packaging is becoming more and more important, and the reliability requirements of cleaning are also getting higher and higher.

In the packaging process of semiconductor devices, flux and solder paste will be used as welding accessories. These welding materials will more or less produce residues during the welding process, and will also be contaminated by some pollutants such as fingerprints, sweat and dust during the manufacturing process. Under the action of air oxidation and moisture, the flux residues and pollutants on the surface are easy to corrode the device, causing irreversible damage, affecting the stability of the device or even failure.

In order to ensure the quality and high reliability of semiconductor devices, cleaning processes and cleaning agents must be introduced during the packaging process.

At present, the semiconductor device packaging industry mainly uses alkaline water-based cleaning and neutral water-based cleaning agents.

The residues of semiconductor packaging and welding auxiliary materials are mainly rosin and organic acids. Both rosin and organic acids contain carboxyl groups, which can be saponified with the alkaline components in alkaline cleaning agents to form organic salts. Therefore, alkaline cleaning agents have a good cleaning effect on the flux residues of semiconductor devices.

However, with the development of semiconductors and the demand for special functions, some devices are assembled from very fragile functional materials, such as sensitive metals such as aluminum, copper, platinum and nickel, ink characters and special labels. These sensitive metals and page functional materials are easily oxidized, discolored, expanded, deformed and detached in an alkaline environment, which greatly limits the widespread application of alkaline water-based cleaning agents in the semiconductor packaging cleaning industry.

Neutral water-based cleaning agents mainly promote the detachment of residues from the surface of semiconductor devices through the penetration and stripping effect of surfactants on residues, thereby achieving the purpose of cleaning. Neutral water-based cleaning agents are neutral pH values and have good compatibility with sensitive metals such as copper, aluminum, nickel, special functional materials, and ink characteristics. Alkaline water-based cleaning agents and neutral water-based cleaning agents have different cleaning mechanisms and different final cleaning effects. Generally speaking, alkaline water-based cleaning agents have stronger cleaning capabilities than neutral water-based cleaning agents, and neutral water-based cleaning agents have higher compatibility than alkaline water-based cleaning agents. The specific cleaning agent used for semiconductor packaging cleaning needs to be selected according to the characteristics of the object being cleaned.