Copyright © Dongguan Lijing Chemical Trading Co., Ltd. All Rights Reserved. Site Map

- +86-13509219524

- dglijingch@yeah.net

- Room 1406, Fuxi Building, No. 33, Keyuan South Road, Guancheng Subdistrict, Dongguan City

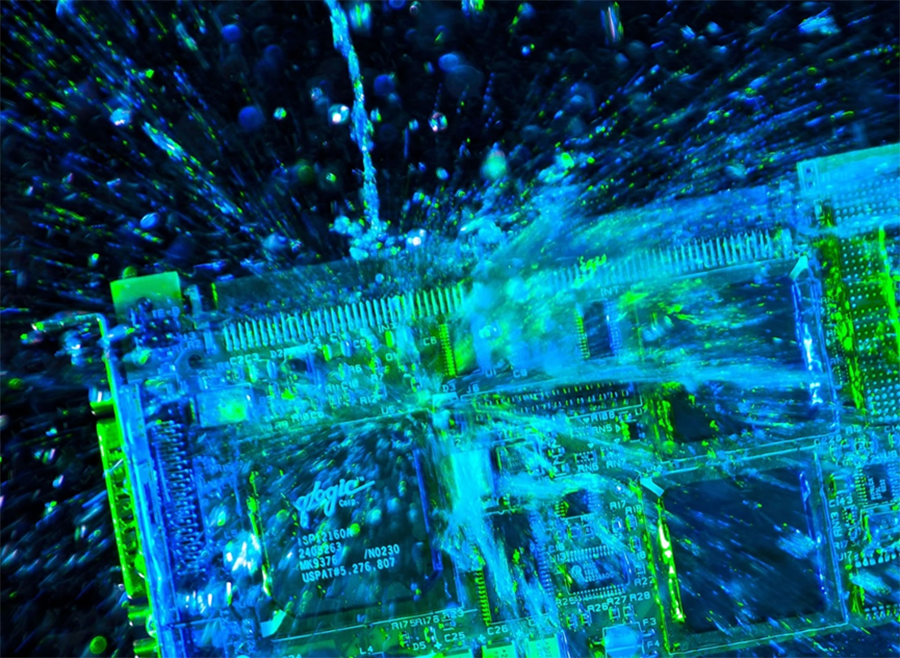

In the production process of SMT electronic components, there are many process flows for PCBA circuit board assemblies. Pollutants such as welding residues will affect the reliability of electronic components and the quality of product appearance. Usually, we choose water-based cleaning process to clean PCBA circuit board assemblies to improve product appearance quality and ensure the reliability of electronic components. But how do we balance the cleanliness of water-based cleaning of PCBA circuit boards and material compatibility issues?

1. Cleanliness of water-based cleaning:

The cleanliness of water-based cleaning needs to be controlled from the cleaning process. The requirements and material factors that affect the cleaning process include circuit density, component support height, residual flux composition, reflow temperature, and the number of heating times before cleaning. Component materials that may be seriously affected by the cleaning process include copper cladding, surface plating, plastic parts, components, labels, device identification, metal alloys, coatings, non-sealed components, and adhesives. The preparation of components and assembly materials (chemicals used in the process include cleaning and surface pretreatment processes) may be seriously affected by the assembly cleaning process. Chemicals used in the process that may affect the cleaning process include SMT solder paste, SMT soldering flux, wave soldering tin bars, wave soldering flux, tin wire for rework, flux, or any other substances that must be removed during the cleaning process.

2. Cleaning factors affected by water-based cleaning process:

The key material compatibility considerations when designing the cleaning process are components, assembly materials, cleaning agents, impact energy applied in the cleaning process, expected process time, temperature and equipment design. Cleaning factors that may affect the cleaning process include cleaning agents, liquid concentration of the washing tank, amount of flux introduced, cleaning equipment, spray pressure, fluid flow, speed and process temperature. These same factors may affect the compatibility of materials. Since the contaminants accumulated in the tank may come from incompatible materials, interactions may also need to be considered based on the use time of the cleaning tank.

3. The influence of material properties and characteristics of components and assemblies:

In order to ensure the reliability of PCB assemblies, it is required to understand the properties and characteristics of the raw materials used to manufacture electronic components and assemblies. When selecting flux, paste, adhesive, substrate, cleaning materials, conformal coating materials and other common interconnect materials, identifying the potential negative impact of the cleaning process on the appearance quality and even the entire component structure is a basic principle of successful engineering design. The actual performance of the material can be different from the theoretical or expected performance in different situations. The performance of different batches of materials varies and may affect the compatibility of the materials. Factors that affect the actual performance of materials, such as cleaning agents, cleaning time, cleaning temperature, cleaning quantity, and impact energy, should be tested to understand the interaction between materials.

The above article is for reference only!