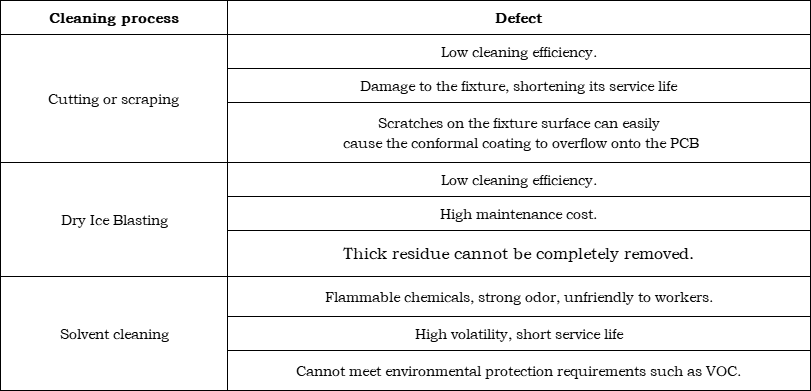

During the process of coating conformal coating on PCBA, the residual conformal coating on the nozzle, track, jig, baffle and pressure strip of the coating equipment needs to be cleaned regularly. How to quickly, efficiently and simply remove the cured conformal coating is a problem that the cleaning industry needs to solve urgently.In the traditional cleaning field, the cleaning of the coating jig is to remove the conformal coating by cutting, scraping, dry ice cleaning, steel brush or brush brushing. These methods cannot meet the needs of large-scale and automated cleaning of equipment, and the cleaning efficiency is low, and the damage to the jig is also large.

During the process of coating conformal coating on PCBA, the residual conformal coating on the nozzle, track, jig, baffle and pressure strip of the coating equipment needs to be cleaned regularly. How to quickly, efficiently and simply remove the cured conformal coating is a problem that the cleaning industry needs to solve urgently.In the traditional cleaning field, the cleaning of the coating jig is to remove the conformal coating by cutting, scraping, dry ice cleaning, steel brush or brush brushing. These methods cannot meet the needs of large-scale and automated cleaning of equipment, and the cleaning efficiency is low, and the damage to the jig is also large.

Some world-renowned conformal coating brand companies do not produce cleaning agents themselves; most niche brand cleaning agents have poor compatibility with conformal coatings of different systems and poor cleaning power. In response to this situation, the engineers of the R&D team of Lijing Chemical have achieved fast, efficient and simple cleaning of conformal coating jigs after years of research and practice.LIJING SJ-20Aqueous cleaning fluid for cleaning coated jigsSJ-20 is an aqueous cleaning fluid used for cleaning coated jigs. It is suitable for removing residues of different types of coating materials, including acrylates, polyurethanes, epoxy resins, UV-curable types, etc. It is also compatible with copper, aluminum, and steel materials on jigs. It effectively cleans different types of three-conformal paint residues, has strong compatibility, will not discolor or corrode copper, aluminum, and nickel metal materials, has a mild formula, is extremely safe to operate, has strong penetration, good solubility, and can quickly penetrate and strip residuesThe process window is wide, and ultrasonic equipment is commonly used for batch cleaning/spray equipment for batch cleaning.

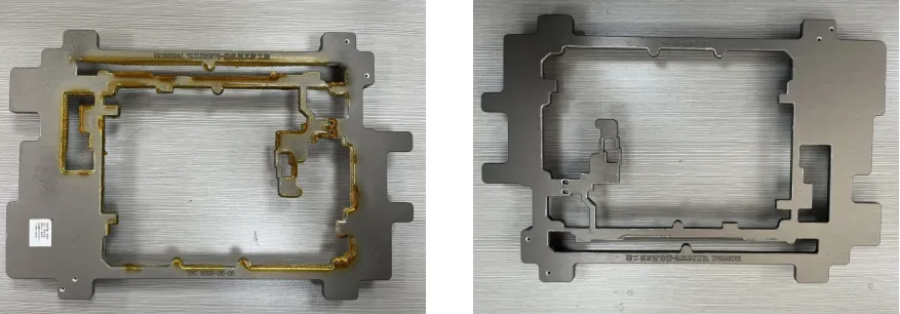

Some world-renowned conformal coating brand companies do not produce cleaning agents themselves; most niche brand cleaning agents have poor compatibility with conformal coatings of different systems and poor cleaning power. In response to this situation, the engineers of the R&D team of Lijing Chemical have achieved fast, efficient and simple cleaning of conformal coating jigs after years of research and practice.LIJING SJ-20Aqueous cleaning fluid for cleaning coated jigsSJ-20 is an aqueous cleaning fluid used for cleaning coated jigs. It is suitable for removing residues of different types of coating materials, including acrylates, polyurethanes, epoxy resins, UV-curable types, etc. It is also compatible with copper, aluminum, and steel materials on jigs. It effectively cleans different types of three-conformal paint residues, has strong compatibility, will not discolor or corrode copper, aluminum, and nickel metal materials, has a mild formula, is extremely safe to operate, has strong penetration, good solubility, and can quickly penetrate and strip residuesThe process window is wide, and ultrasonic equipment is commonly used for batch cleaning/spray equipment for batch cleaning. Case sharing 1Experimental designAt the request of the customer, fully automatic spray cleaning equipment and ultrasonic cleaning equipment were used for cleaning, and water-based cleaning agents were used to evaluate the cleaning effect of three-conformal paint jigs. The customer prepared two jigs to be cleaned.Experimental resultsAfter the laboratory experiment using fully automatic spray equipment and water-based cleaning agents, all residues on the jigs can be cleaned at one time. See Figure 1 below for a comparison before and after cleaning.

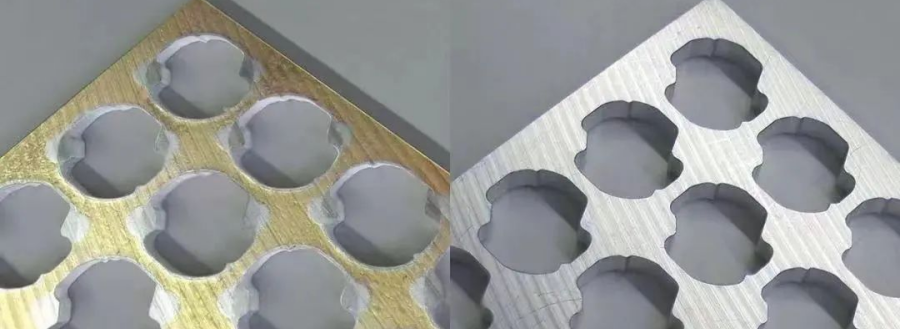

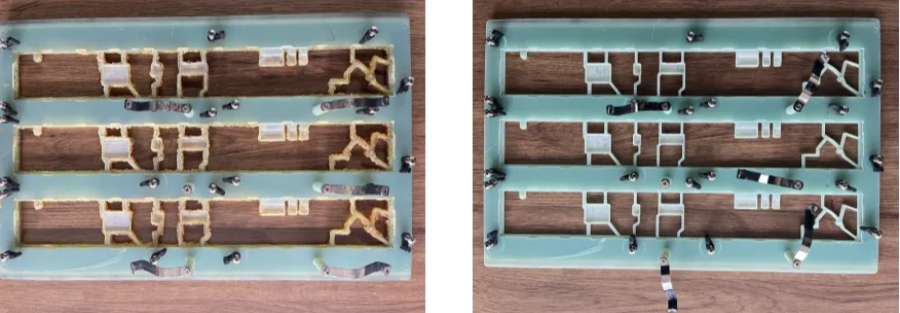

Case sharing 1Experimental designAt the request of the customer, fully automatic spray cleaning equipment and ultrasonic cleaning equipment were used for cleaning, and water-based cleaning agents were used to evaluate the cleaning effect of three-conformal paint jigs. The customer prepared two jigs to be cleaned.Experimental resultsAfter the laboratory experiment using fully automatic spray equipment and water-based cleaning agents, all residues on the jigs can be cleaned at one time. See Figure 1 below for a comparison before and after cleaning.

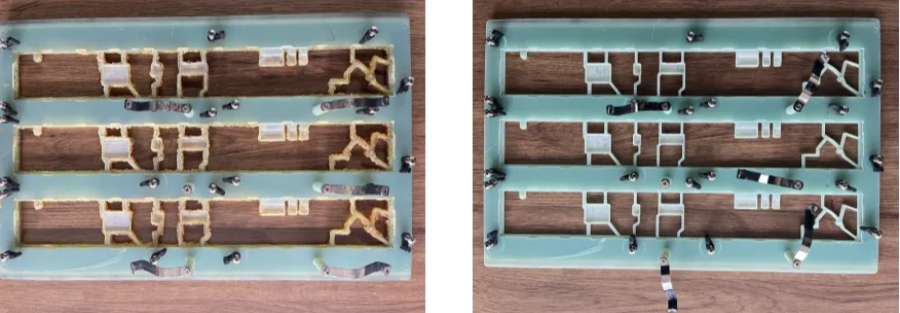

Figure 1 Before cleaning (left) and after cleaning (right)

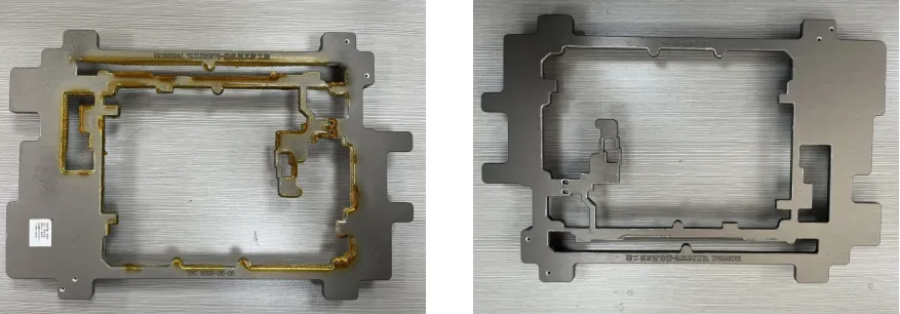

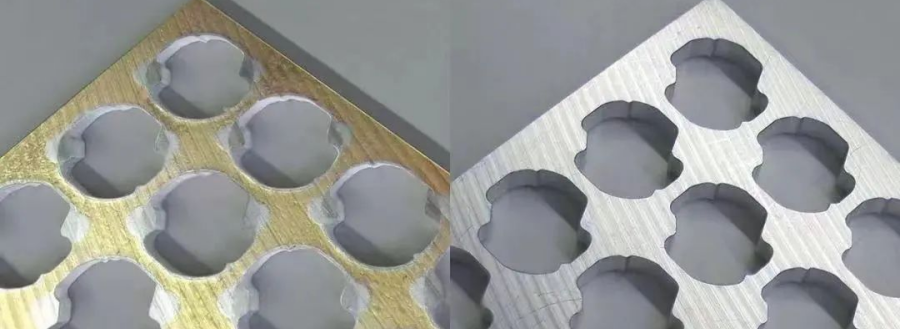

After the laboratory experiment using ultrasonic cleaning equipment and water-based cleaning agents, all residues on the fixtures can be cleaned at one time. See Figure 2 below for a comparison before and after cleaning.

Figure 2 Before cleaning (left) and after cleaning (right)

About usLijing Chemical was established in 2004. The company's business is centered in Dongguan and radiates the entire Pearl River Delta. Lijing Chemical is a high-tech enterprise engaged in the research and development, production and sales of water-based cleaning fluids. Lijing Chemical has been committed to the innovation and development of advanced cleaning technologies to meet your production cleaning needs.If you want to know more about Lijing Chemical, please follow us!